HOSTMilano is one of the biggest Hospitality Shows in the world. It happens every two years and IMA Group are proud to be unveiling new technology at this world-renowned event!

The IMA Coffee Hub's commitment to research into new sustainable projects and technologies is on show at HOSTMilano.

Visit IMA Coffee Hub at HOSTMilano Hall 22P – Stand K47 K 57 L48 L58

IMA Coffee Hub strives to answer the needs of the global coffee industry and engineer quality solutions to enhance the performance of its customers. To meet the needs of a rapidly evolving market, IMA Coffee Hub covers all aspects of the processing and packaging processes, from consultancy and design to production planning and turnkey solutions.

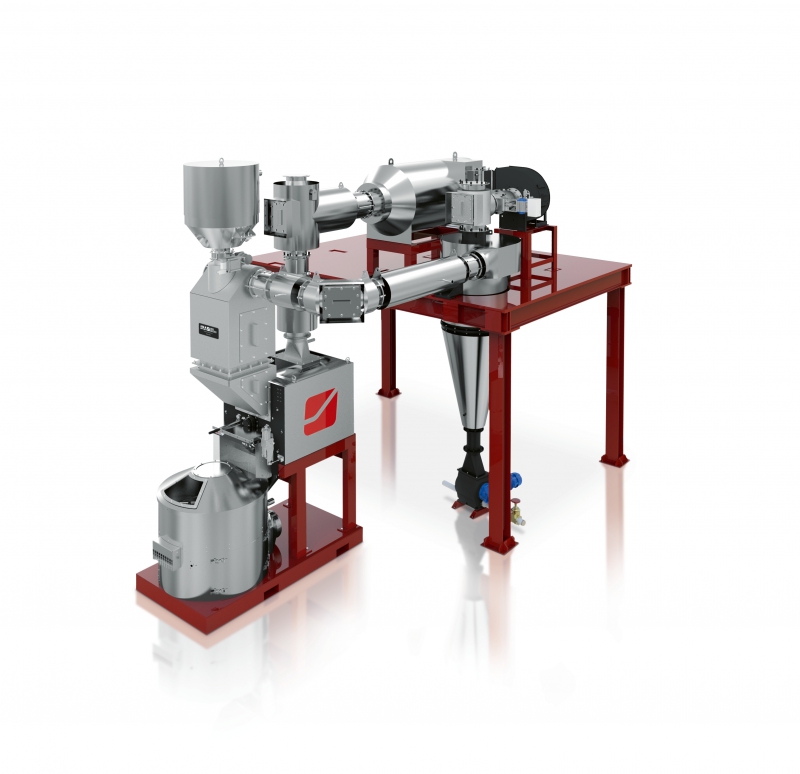

“The perfect balance of the IMA Coffee Hub will be visible at HOSTMilano, October 13-17, where we will be exhibiting some of the most reliable solutions for coffee roasting and packaging. Starting from a classic-style product, the IMA Petroncini TTA60, the strongest roaster ever, up to the most sustainable and flexible solution for coffee roasting: the IMA Petroncini TMR roaster.” says Nicola Panzani, CEO at IMA Petroncini and Sales Director at IMA Coffee Hub.

“On show the TMR25 LAB, the perfect scale-down of IMA Petroncini industrial model, meant for lab purposes. TMR25 makes it possible to perform new roasting profiles, testing new blends and transferring the roasting parameters on the industrial roaster to launch the production. That’s possible thanks to Orchestra, the new roasting control applied on TMR models, capable of self-tuning the machine parameters, thus enabling the roasting technologist to achieve constant roasting results over time, especially for products such as pods and capsules.” Panzani says.

Another important key feature of TMR is its energy saving system. The TMR uses just one burner as a heat generator and after burner to reduce carbon dioxide, NOx and VOC emissions. The heat recirculation allows, on average, 30 to 35 per cent energy saving, compared to traditional roasters, and this focus on sustainability is now more important than ever.

During the last years, IMA Coffee has strengthened its commitment to reduce the environmental impact along the coffee production chain in collaboration with OPENLab, IMA Group’s network of technological laboratories and testing areas dedicated to research on sustainable materials, technologies, and production optimisation processes. This environmental commitment applies through testing alternative processes to preserve the resources, adapting filling and sealing technology to the new packaging materials to minimize the packaging waste.

“Coffee capsules are complex structures where the capsule body, lidding, and filter must be precisely designed to deliver a consistently high-quality experience. Before the capsules even reach final consumers, it’s key that these components perform well during assembly and filling, during brewing, and on the shelf. Nowadays, some companies are investing in sustainable packaging techniques to offset the environmental effect of traditional plastic packaging on the planet.” says Alessandro Nobili, Head of Product and Project Management at IMA Coffee | Packaging Solutions.

“Demand for compostable coffee capsules is expected to grow as customers become more health conscious and aware of negative environmental repercussions of coffee capsule packaging. Thanks to OPENLab, we can analyse new sustainable and innovative materials such as compostable, paper-based, or ultra-thin film, before they are commercially available, developing projects to respond to customer needs and studying alternative processes and material specifications.” Nobili says.

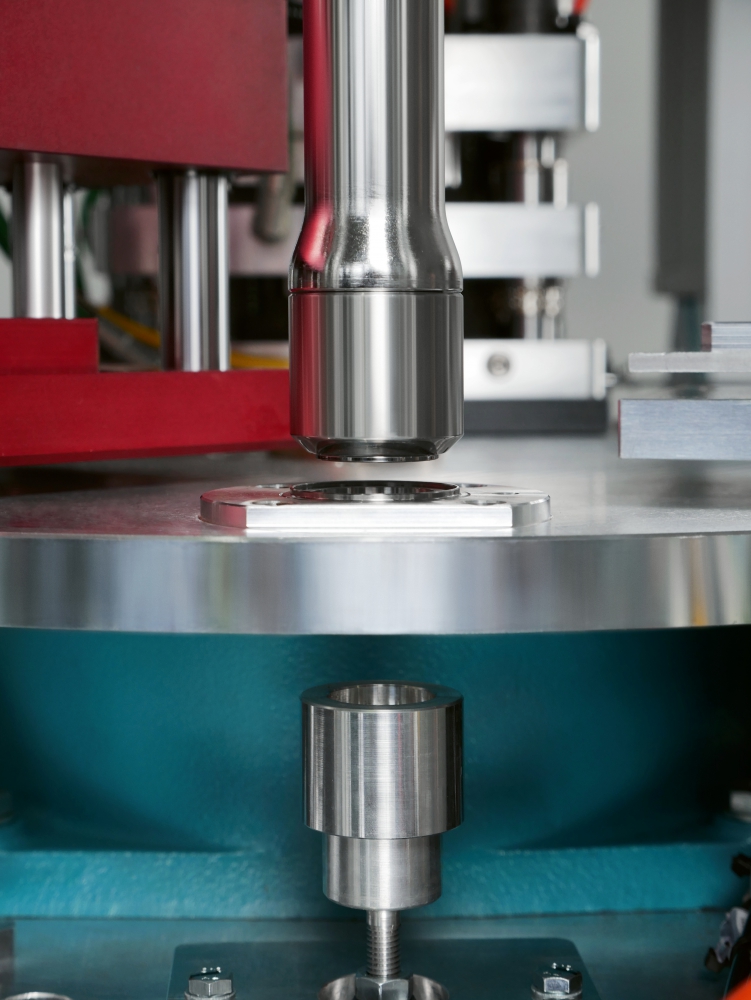

IMA OPENLab is a place where knowledge and skills coming from machines, packaging manufacturing and customers converge to develop the customer project. Compatibility testing on capsules, filters, and top lid films are performed to identify and achieve optimum material sealing parameters and limits, as well as a suitable set-up of IMA packaging machinery to handle the capsules successfully.

At HOSTMilano, IMA will be officially presenting the latest projects developed at IMA OPENLab alongside the new SB1 LAB, an extremely compact rotary machine for the filling and sealing of single capsules, meant for lab purposes and small production, and the SR4N, designed for medium production volumes. SR4N is a reliable solution for handling compostable capsules ensuring high technological standards and high dosing accuracy, in a compact footprint. Thanks to a high degree of automation and flexibility, every filler from the IMA Coffee portfolio can handle all types of capsules, whatever material they are made of, be it compostable materials, aluminium, or plastic.

"IMA Coffee’s expertise and specific know-how for each type of product allow us to configure complete customised lines for every production requirement, offering a combination of primary, secondary and end-of-line packaging solutions for traditional applications or innovative technologies to achieve the highest levels of productivity, efficiency and flexibility in size changeover and capsule material handling.” Nobili says.

The dualism that characterises IMA Coffee Hub converges in the IMA Coffee Lab, a coffee laboratory installed at IMA Petroncini production site in Italy, housing a pilot plant running all processing stages, from green coffee receiving and cleaning to roasting and grinding up to capsule packaging.

IMA Coffee Lab technicians and consultants are always ready to find the ideal processing and packaging solutions to achieve the desired quality and taste. IMA can develop a tailor-made coffee plant examining all aspects on site at the Coffee Lab. IMA’s experts study the maximum production efficiency for the customer by carrying out trials and getting immediate answers thus evaluating the processing stages and final coffee quality prior to commissioning the plant.

Visit IMA Coffee Hub at HOSTMilano Hall 22P – Stand K47 K 57 L48 L58

For more information, visit www.ima.it/coffee.