Gaggia BC (Before Craig)

Gaggia BC (Before Craig)

The tools laid out and ready for action.

The tools laid out and ready for action.

Aluminium corrosion on the frame.

Aluminium corrosion on the frame.

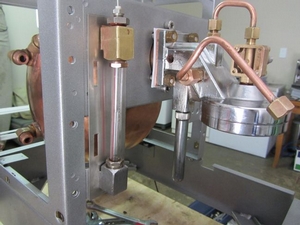

New Pump, Motor, Control box, Piping,O-rings, Seals and gaskets.

New Pump, Motor, Control box, Piping,O-rings, Seals and gaskets.

The brass plate with a paper gasket that shuts the group off from the boiler. I replaced the paper gasket with a PTSE gasket. Because, obviously, it will last longer guys.

The brass plate with a paper gasket that shuts the group off from the boiler. I replaced the paper gasket with a PTSE gasket. Because, obviously, it will last longer guys.

Parts about to go to the sand blaster and powder coater.

Parts about to go to the sand blaster and powder coater.

Broken pick 1 of 2, trying to get the rubber' group gasket out. These gaskets get super hard over time.

Broken pick 1 of 2, trying to get the rubber' group gasket out. These gaskets get super hard over time.

Parts on bench before Hot Citric Acid soak and polish, The boiler was not too scaled up and cleaned nicely.

Parts on bench before Hot Citric Acid soak and polish, The boiler was not too scaled up and cleaned nicely.

It's in the detail. The top one is the badge before sanding and polishing.

It's in the detail. The top one is the badge before sanding and polishing.

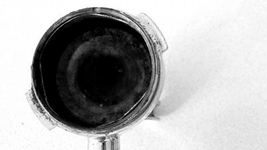

My BFF( best friend forever). I hit it, heated it, soaked it in releasing fluid and acid, cut a flat groove in it to use a flat screw driver, drilled it. and eventually BEAT IT! mwahahahaha

My BFF( best friend forever). I hit it, heated it, soaked it in releasing fluid and acid, cut a flat groove in it to use a flat screw driver, drilled it. and eventually BEAT IT! mwahahahaha

Parts after acid soak and rubbing with a polishing compound and fine steel wool.

Parts after acid soak and rubbing with a polishing compound and fine steel wool.

What kept me going at 2am, Colombian espresso on my La Cimbali M20 Lever.

What kept me going at 2am, Colombian espresso on my La Cimbali M20 Lever.

I prefer using silver as a colour on the frame, it makes it easier to work on and the chrome, copper and brass look good against it.

I prefer using silver as a colour on the frame, it makes it easier to work on and the chrome, copper and brass look good against it.

Punching some holes in for the bolts in 5mm thick PTFE gaskets for the boiler flange.

Punching some holes in for the bolts in 5mm thick PTFE gaskets for the boiler flange.

2.5mm thick Silicone wiring for the element and 1.5 for the rest of the machine. New stainless steel bolts all round.

2.5mm thick Silicone wiring for the element and 1.5 for the rest of the machine. New stainless steel bolts all round.

.png)

.png)

.jpg)